Metal Sheet transfer system that picks up large sheets

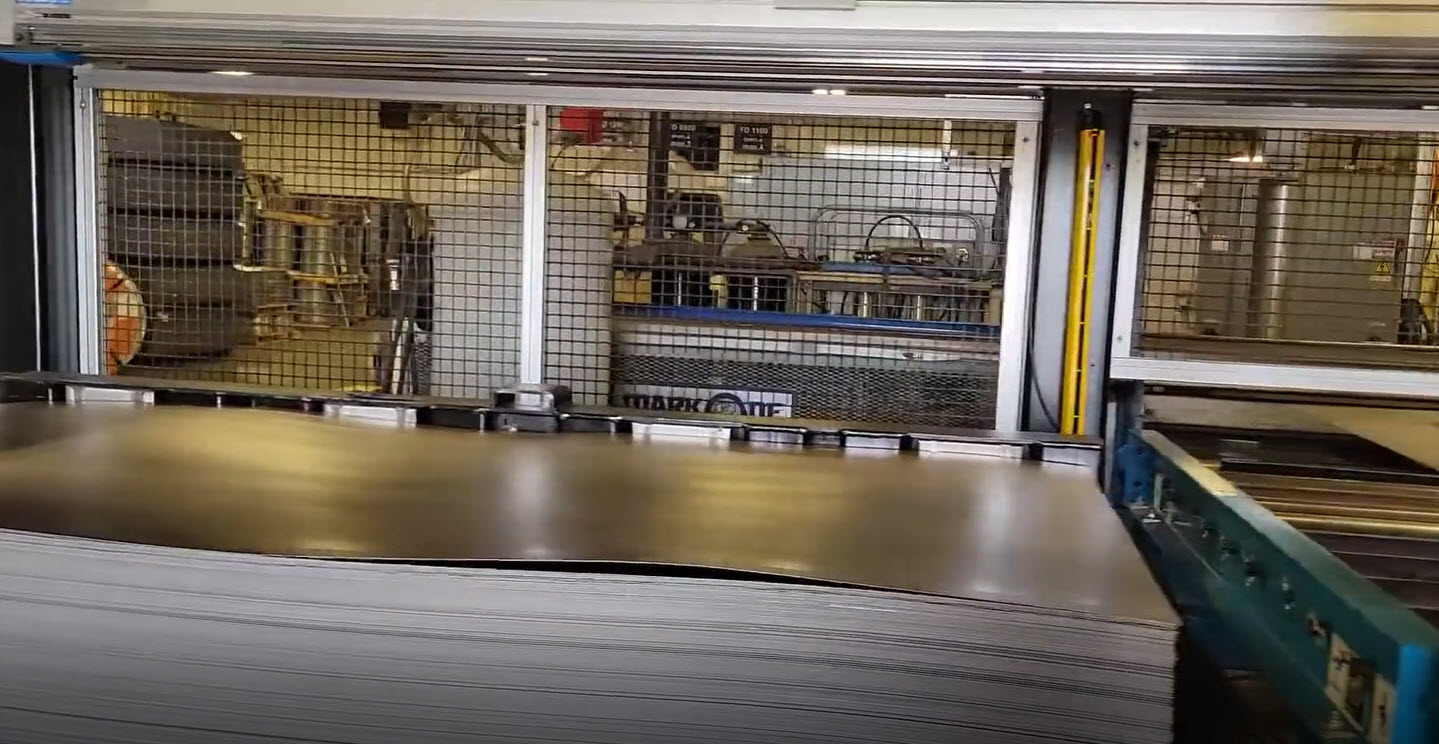

Feed stacks are loaded from both sides of the machine on hydraulic lift tables

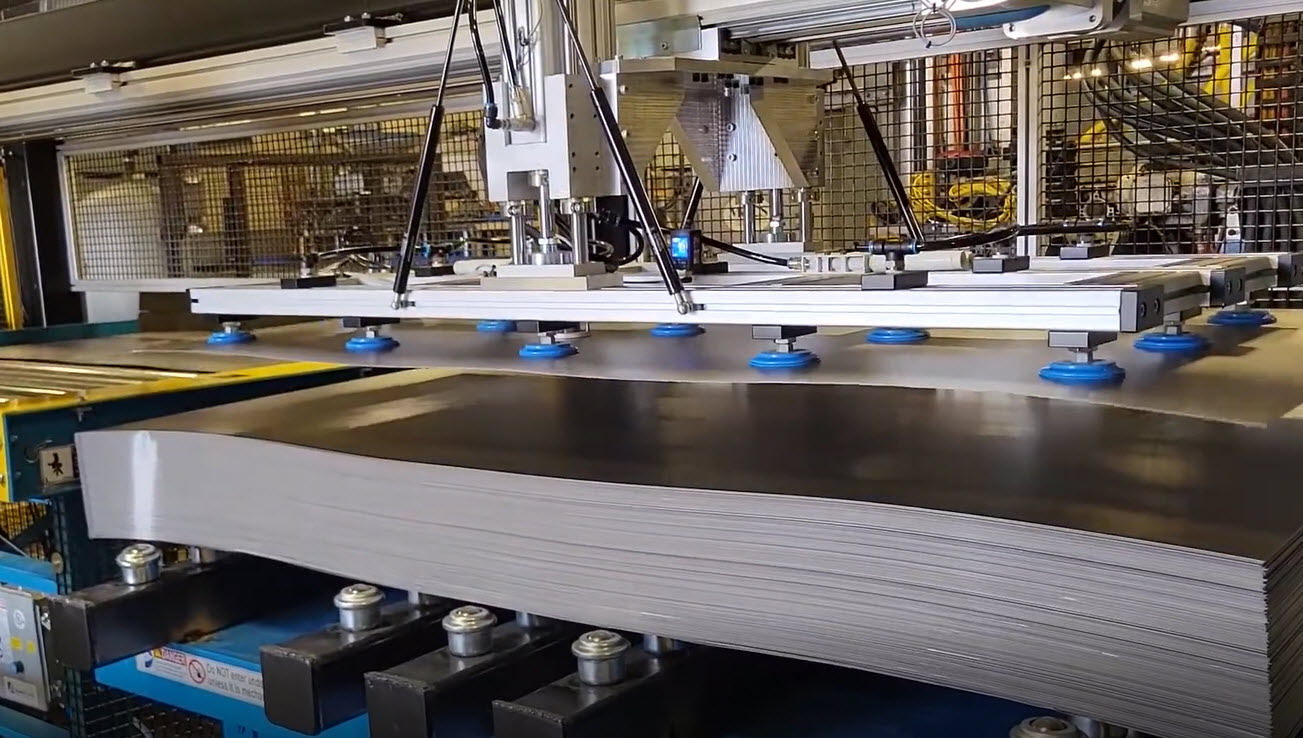

Vacuum transfer system loads sheets onto a roller conveyor

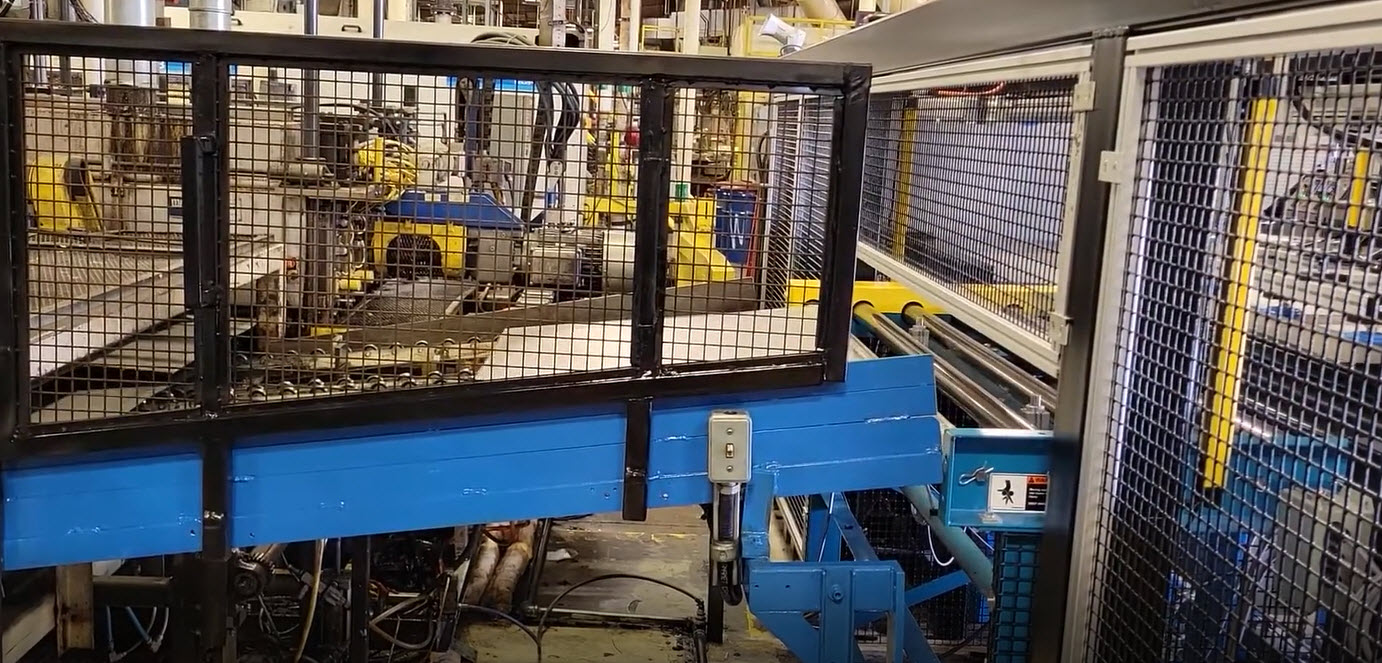

Feeds customer’s welder to produce 55 gallon drums

Metal Sheet transfer system that picks up large sheets

Feed stacks are loaded from both sides of the machine on hydraulic lift tables

Vacuum transfer system loads sheets onto a roller conveyor

Feeds customer’s welder to produce 55 gallon drums